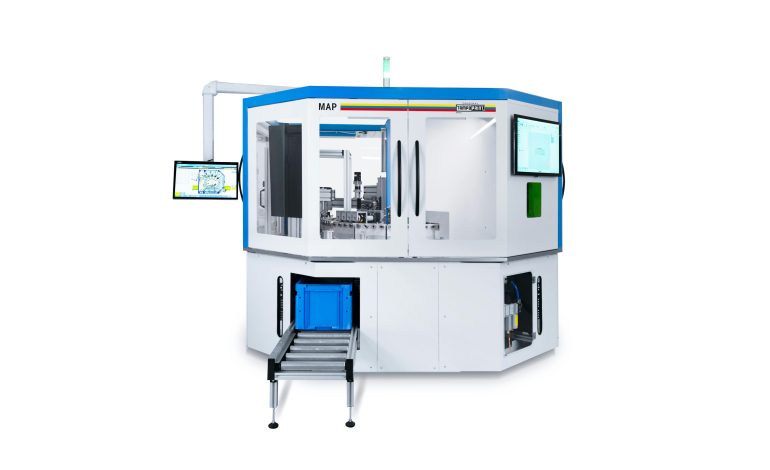

Role of laser sensor systems in automation and flexible manufacturing

Laser sensor systems have quickly emerged as game-changers in industrial automation, helping manufacturers improve precision, efficiency, and flexibility during manufacturing processes. Industries increasingly adopt flexible manufacturing to respond to dynamic market demands; as these processes adapt further toward meeting these market requirements, laser sensor systems become indispensable tools – this article examines their significance within automation as well as their transformative effect in the flexible manufacturing realm.

Laser Sensor Systems: Unveiling Technology

Laser sensor systems use laser beams to detect and measure various attributes, including distance, position, and even composition of objects within their range. Their technology utilizes light reflection principles for accurate real-time data collection allowing accurate real-time acquisition across many industries ranging from automotive and electronics to pharmaceuticals and aerospace. These highly versatile sensors find applications in automotive dealerships, electronics outlets as well as pharmaceutical firms.

Automating Precision in Automation

One of the key advantages of laser sensor systems lies in their precision. Precision is of critical importance in automated manufacturing processes; therefore, these sensors play a pivotal role in making sure machinery works precisely and without error. They help measure dimensions or locate components on production lines – contributing towards minimizing errors and optimizing quality control measures laser automation.

Manufacturing Process Efficiency Improvement Strategies

Efficiency in manufacturing operations is of utmost importance, and laser sensor systems excel in streamlining various processes. Their rapid data acquisition enables machines to make split-second decisions based on real-time information; especially useful in high-speed production environments where instant measurements must be made quickly and precisely. By decreasing cycle times and minimizing downtime, laser sensor systems contribute greatly towards overall increases in manufacturing operations’ efficiencies.

Enabling Adaptive Manufacturing through Flexibility

Laser sensor systems play an integral part in helping businesses adapt quickly to market fluctuations and customized production requirements, such as market fluctuations or variations. Laser sensors serve a vital purpose by providing feedback for machines to seamlessly switch tasks without needing extensive reprogramming or downtime. They detect changes to production environments like new materials being introduced or variations occurring with product specs requiring changes; and provide necessary feedback so machines adapt seamlessly between tasks. This adaptability enables production lines to quickly switch products without lengthy reprogramming processes being necessary between jobs.

Improving Safety in Automated Environments

Safety in industrial settings has always been of utmost concern, particularly as automation takes hold. Laser sensor systems play an integral part in creating safer work environments by offering precise detection and monitoring capabilities that contribute significantly to creating safe work environments. Laser sensors detect objects, people, or obstacles instantly so automated systems can immediately respond with automated responses to prevent accidents – from collision avoidance in robotic applications to personnel safety near machinery – laser sensor systems act as vigilant guardians by mitigating potential risks and creating safer workplace environments.

Applications in Different Industries

Laser sensor systems demonstrate their adaptability across numerous industries with their widespread usage. Automotive manufacturing utilizes these sensors for precise component positioning and quality control as well as autonomous vehicle navigation; electronics production relies upon laser sensors for placing tiny components accurately onto circuit boards while pharmaceutical production uses laser sensors for precise drug dispensing whereas aerospace industry organizations utilize them in tasks like aircraft assembly and maintenance.

Challenges and Future Developments in the Manufacturing Sector

Although laser sensor systems have revolutionized automation and flexible manufacturing, there remain challenges with using them effectively. Adverse environmental conditions like dust, smoke, or extreme temperatures may hinder laser sensor performance; researchers and engineers are actively developing robust systems capable of withstanding harsh environments; advances in artificial intelligence/machine learning technology are being integrated with laser sensor tech to enhance predictive abilities allowing systems to anticipate any issues before them occurring.

Conclusion

Laser sensor systems have opened a whole new world of precision, efficiency, and flexibility in manufacturing. As revolutionary systems drive innovation within industries to adapt quickly to ever-evolving demands while taking full advantage of flexible manufacturing. Laser sensor technology may have even greater roles to play as it continues to progress; likely making production safer, smarter, and more adaptive processes than ever. Embracing such transformative technology should not just be considered optional but an obligation for industries looking to remain competitive within an ever-evolving global marketplace.